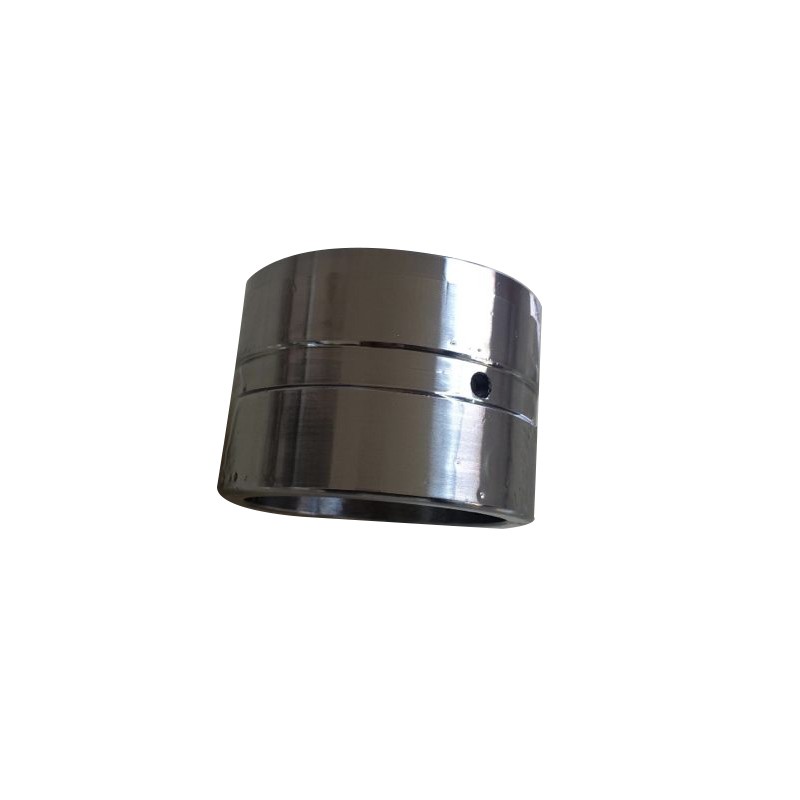

China wholesale Bulldozer Wear Parts - Bucket Bushing Excavator – Pingtai

China wholesale Bulldozer Wear Parts - Bucket Bushing Excavator – Pingtai Detail:

The bucket pin and bucket bushing (sliding bearing) hinged parts are commonly used in excavators, loaders, bulldozers and other engineering machinery operating devices. Qualified articulated parts should have a reasonable fit clearance, which can store grease, to ensure that the bucket pin and bucket bushing in relative motion to reduce wear and resistance. The reasonable fit clearance of the hinged parts can leave a certain space for the thermal expansion generated when the pin shaft moves relative to the shaft sleeve, so as to prevent sintering. If the hinge gap is super poor, it will cause the pin shaft and shaft sleeve to fit loose, produce vibration, impact and eccentric wear, resulting in aggravation of wear or shaft fracture, and even lead to major equipment and personal accidents. Over-poor hinge clearance will also cause deviation and shaking of the operation device of construction machinery, which will lead to the decrease of its operating accuracy and efficiency. Therefore, keeping reasonable hinge clearance is an important link to improve the reliability of construction machinery.

Shafting parts should be selected according to different working conditions and use requirements of different materials and different heat treatment specifications (such as tempering, normalizing, quenching, etc.), in order to obtain a certain strength, toughness and wear resistance.

The raw material of the bucket bushing produced by our company is 40Cr steel, which is suitable for medium precision and high speed shaft parts. This kind of steel has better comprehensive mechanical properties after quenching and tempering.

Bearing steel GCr15 and spring steel 65Mn, after tempering and quenching and high frequency surface quenching, the surface hardness can reach 50 ~ 58HRC, and has high fatigue resistance and good wear resistance, can make more high precision shaft.

45 steel is a common material for shaft parts, it is cheap after tempering (or normalizing), can get better cutting performance, and can get higher strength and toughness and other comprehensive mechanical properties, Widely used in machine building, this steel has excellent mechanical properties.But this is a kind of medium carbon steel, quenching performance is not good, 45 steel can be hardened to HRC42~46.So if you need surface hardness, and want to play to the superior mechanical properties of 45# steel, often 45# steel surface quenching (high frequency quenching or direct quenching), so that you can get the required surface hardness.

| Place of origin: | China |

| Brand name: | PT’ZM |

| Model number | |

| Price: | Negotiate |

| Packaging details: | Fumigate seaworthy packing |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 100000 PCS/month |

| Material: | 40cr |

| Technique: | Forging |

| Finish: | Smooth |

| Hardness: | HRC48-60 |

| Quality: | mining operation heavy duty high-end quality |

| Warranty time: | 24 months |

| After-sales service: | Video technical support,Online support |

| Color: | Customer required |

| Application: | Bulldozer & Crawler excavator |

|

Description |

Part No. |

Size |

|

Bucket bushing |

707-76-80010 |

80-95-85 |

|

Bucket bushing |

205-70-67150 |

80-95-90 |

|

Bucket bushing |

3048327 |

80-95-95 |

|

Bucket bushing |

206-70-13130 |

80-95-100 |

|

Bucket bushing |

LKU 0075 |

80-95-105 |

|

Bucket bushing |

1072-01730 |

80-95-125 |

|

Bucket bushing |

1072-02110 |

80-100-140 |

|

Bucket bushing |

2438U 1106 S5 |

85-95-90 |

|

Bucket bushing |

2438 U1108 S2 |

85-90-110 |

|

Bucket bushing |

KRV 0345 |

85-100-80 |

|

Bucket bushing |

YN01V0001S002 |

90-100-90 |

|

Bucket bushing |

205-70-66550 |

90-105-70 |

|

Bucket bushing |

207-70-33160 |

90-105-90 |

|

Bucket bushing |

7Y-2396 |

90-106-90 |

|

Bucket bushing |

205-70-65760 |

90-105-130 |

|

Bucket bushing |

205-70-65762 |

90-105-135 |

|

Bucket bushing |

931858 |

90-110-100 |

|

Bucket bushing |

207-70-11210 |

100-115-90 |

|

Bucket bushing |

3028854 |

100-115-100 |

|

Bucket bushing |

707-76-10140 |

100-115-105 |

|

Bucket bushing |

3036659 |

100-115-110 |

|

Bucket bushing |

707-76-10160 |

100-115-115 |

Product detail pictures:

Related Product Guide:

We also provide item sourcing and flight consolidation solutions. We have now our very own manufacturing facility and sourcing place of work. We could provide you with nearly every kind of merchandise associated to our merchandise variety for China wholesale Bulldozer Wear Parts - Bucket Bushing Excavator – Pingtai , The product will supply to all over the world, such as: Costa Rica, Albania, Niger, With excellent products, high quality service and sincere attitude of service, we ensure customer satisfaction and help customers create value for mutual benefit and create a win-win situation. Welcome customers all over the world to contact us or visit our company. We will satisfy you with our professional service!

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.