D275 Sprocket Segment Rim Group Komatsu Bulldozer

Komatsu D275 crawler bulldozer series of professional production undrecarriage parts.We not only supply OEM undercarriage parts but also aftermarket, and all products come with an industry leading warranty of 6 months to 2 years.

D275 sprocket segment rim groups are specifically designed to provide extended life and durability for the toughest working conditions. We offer sprockets for crawlers, dozers and excavators.

Forging sprocket segment and special heat treatment technique ,so reach the best wear-resistance and prolong life time to maximum extent.Vertical machining center CNC processing production, make the size more accurate, more beautiful appearance.

Having wide choice range.The sprocket segment is applicable to special model of crawler type excavators and bulldozer from 0.8T to 100T. It is widely applied in bulldozers and excavators of Caterpillar, komatsu, Hitachi,Volvo and Doosan etc.

The Komatsu D275 Crawler bulldozer combines pure power with dynamic versatility, making it the perfect machine for a heavy bulldozer weighing more than 110,000 pounds.This machine is powered by a turbocharged and emissions certified 2238 S6D170-4 diesel engine with over 410 HP and 1800 RPM.With a top speed of 7.4 MPH forward and 9.3 MPH in reverse, the Komatsu D275 is fast on tracks while putting a heavy load on the undercarriage.Regular maintenance of undercarriage fittings is important to extend the life of komatsu D275 series crawler bulldozer with qualified and high quality replacement parts.Please feel free to contact us.

|

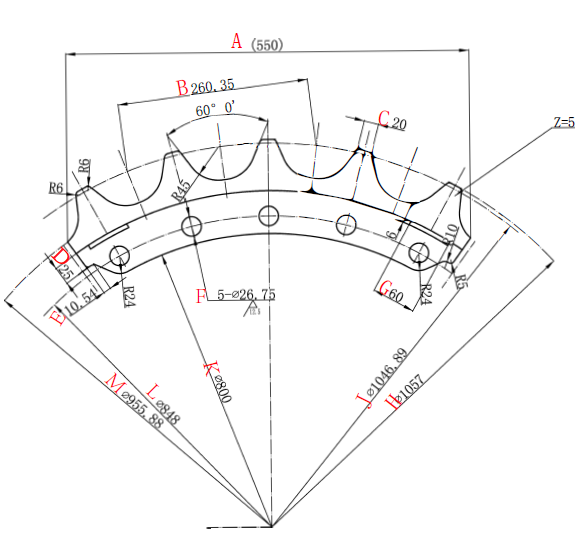

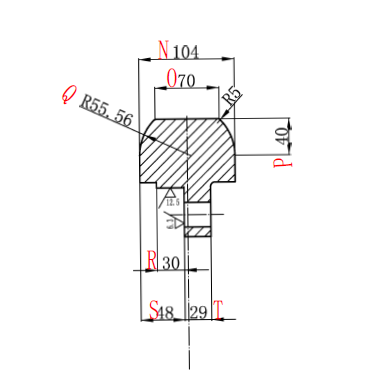

Product detail information |

|

|

Description: |

D275 sprocket segment rim group 17M-27-41630- komatsu bulldozer |

|

Place of origin: |

China |

|

Brand name: |

PT'ZM |

|

Model number |

D275 |

|

Brand: |

Komatsu |

|

Parts number |

17M-27-41630 |

|

Price: |

Negotiate |

|

Packaging details: |

Fumigate seaworthy packing |

|

Delivery time: |

7-30 days |

|

Payment term: |

L/C T/T |

|

Price term: |

FOB/ CIF/ CFR |

|

Minimum order quantity: |

1 PC |

|

Supply Ability: |

10000 PCS/month |

|

Material: |

35MnB |

|

Technique: |

Forging |

|

Finish: |

Smooth |

|

Hardness: |

HRC48-55, deepth 5-8mm |

|

Quality: |

mining operation Heavy duty |

|

Warranty time: |

24 months |

|

After-sales service: |

Video technical support,Online support |

|

Color: |

Yellow or Black or Customer required |

|

Application: |

Crawler Bulldozer |

| Model | A | B | C | D | E | F | G | H | J |

| D275 | 550 | 260.35 | 20 | 25 | 10.54 | 26.75 | 60 | 1057 | 1046.89 |

| Model | K | L | M | N | O | P | Q | R | S | T |

| D275 | 800 | 848 | 955.88 | 104 | 70 | 40 | R55.56 | 30 | 48 | 29 |

D275A-5, D275AX-5