Factory Directly supply Excavator Production Equipment Bucket Teeth Tooth Tip Point High Quality Mining Get Industry Casting Super V V39sdx V39

It adheres for the tenet “Honest, industrious, enterprising, innovative” to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Factory Directly supply Excavator Production Equipment Bucket Teeth Tooth Tip Point High Quality Mining Get Industry Casting Super V V39sdx V39, Welcome mates from all over the globe come to go to, manual and negotiate.

It adheres for the tenet “Honest, industrious, enterprising, innovative” to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Bucket Teeth, Tooth-Long, Faced with the vitality of the global wave of economic integration, we’ve been confident with our high-quality merchandise and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.

The process flow of excavator bucket teeth: sand casting, forging casting, precision casting.

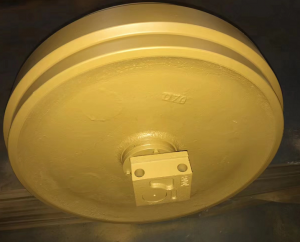

Excavator bucket tooth is an important consumable part on the excavator. It is similar to human teeth. It is a combination bucket tooth composed of tooth base and tooth tip, and the two are connected by the pin shaft. Because the bucket tooth wear failure part is the tooth tip, as long as the replacement of the tip can be.

Classification according to the use environment of excavator bucket teeth. Excavator bucket teeth can be divided into rock teeth (used for iron ore, stone ore, etc.), earthwork teeth (used for digging soil, sand, etc.), conical teeth (used for coal mine).

Excavator bucket teeth can be divided into horizontal pin bucket teeth (Hitachi excavator), horizontal pin bucket teeth (Komatsu excavator, Caterpillar excavator, Daewoo excavator, Kobelco excavator, etc.), rotary digging bucket teeth (V series bucket teeth).

| Product | |

| Description: | BUCKET TEETH MINING OPERATION HEAVY DUTY |

| Place of origin: | China |

| Brand name: | PT’ZM |

| Model number | |

| Price: | Negotiate |

| Packaging details: | Plywood case |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 10000 PCS/month |

| Material: | Alloy steel |

| Technique: | Precision Casting / Forging |

| Finish: | Smooth |

| Hardness: | HRC45-55 |

| Quality: | mining operation heavy duty |

| Warranty time: | 24 months |

| After-sales service: | Video technical support, Online support |

| Color: | Yellow or Red or Black or Customer required |

| Application: | Excavator |

Excavator bucket teeth under normal working conditions for 3 days (about 36 hours) will fail to qualify as unqualified products. There are obvious furrow scratches on the surface of bucket teeth and a small amount of plastic deformation at the tip. The force analysis of the bucket tooth working face and the excavated object contact, in a complete excavation process in different stages of different stress, the tip part of the first contact with the material surface, because the speed is fast, the tip of the bucket tooth by a strong impact. If the bucket tooth yield is low, it will produce plastic deformation at the tip. The unqualified bucket teeth were ground, polished and corroded, and found to be light gray around and dark in the middle, indicating that the bucket teeth were cast inserts. The main alloy components (mass fraction %) are 0.38C, 0.91Cr,0.83Mn and 0.92Si.The mechanical properties of metal materials depend on the composition and heat treatment process of the material factory.

Bucket tooth performance analysis by MLD-10 wear test machine wear test. The wear resistance of the matrix and inserts is better than that of the quenched 45 steel under the condition of small impact wear. At the same time, the wear resistance of the matrix and the inserts is different. The matrix is wear-resistant than the inserts. The composition on both sides of the matrix and the inserts is close to that in the bucket teeth. The insert in the bucket tooth is mainly to play the role of cold iron. During the casting process, the matrix grain was refined to improve its strength and wear resistance. Due to the influence of casting heat, the inserts produce similar structures in the welding heat affected zone, which does not play a role in enhancing the wear resistance. If appropriate heat treatment is carried out after casting to improve the structure of the inserts, the flax resistance and service life of the bucket teeth will be significantly improved.

1.You are a trader or a manufacture?

We are a manufacturer with export rights. Our factory located on Quanzhou Nanan city Fujian province China. We have more than thirty years experience in this industry.

2.How can I be sure the part will fit my bulldozer?

Please sugesst us the model number or the original number of the parts, we will provide drawings or measure the physical size and confirm with you.

3.What is your minimum order?

It depends on what kind of product you buy. If it is a regular product and we have stock, there is no need for the MOQ.

4.Can you help the customers develop new products?

Our technical development department is specialized in developing new products for customers. Customers need to provide drawings, dimensions or real samples for our reference.

5.What is your lead time?

The normal delivery time is about one month, If we have stock for about a week

6. How about the payment terms?

T/T or L/C. other terms also negotiated.

7.Can you make products with our brand?

Sure , we are welcome to cooperate as customized service.

OEM/ODM is welcome, From the concept to finished goods, we do all (design, prototype reviewing, tooling and production) in the factory.

1.One year warranty,free replacement for broken ones with abnormal wear life.

2.Product customization OEM /ODM order.

3.Provide on line or video technical support to our customers.

4.Help you to develop your market with our high quality and best service.

5.VIP treatment to our exclusive agent.

It adheres for the tenet “Honest, industrious, enterprising, innovative” to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Factory Directly supply China Excavator Production Equipment Bucket Teeth Tooth Tip Point High Quality Mining Get Industry Casting Super V V39sdx V39, Welcome mates from all over the globe come to go to, manual and negotiate.

It adheres for the tenet “Honest, industrious, enterprising, innovative” to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Factory Directly supply China Excavator Production Equipment Bucket Teeth Tooth Tip Point High Quality Mining Get Industry Casting Super V V39sdx V39, Welcome mates from all over the globe come to go to, manual and negotiate.

Factory Directly supply China Bucket Teeth, Tooth-Long, Faced with the vitality of the global wave of economic integration, we’ve been confident with our high-quality merchandise and sincerely service to all our customers and wish we can cooperate with you to create a brilliant future.