Hot-selling Excavator Final Drive Parts - Carrier Roller Mining Operation – Pingtai

Hot-selling Excavator Final Drive Parts - Carrier Roller Mining Operation – Pingtai Detail:

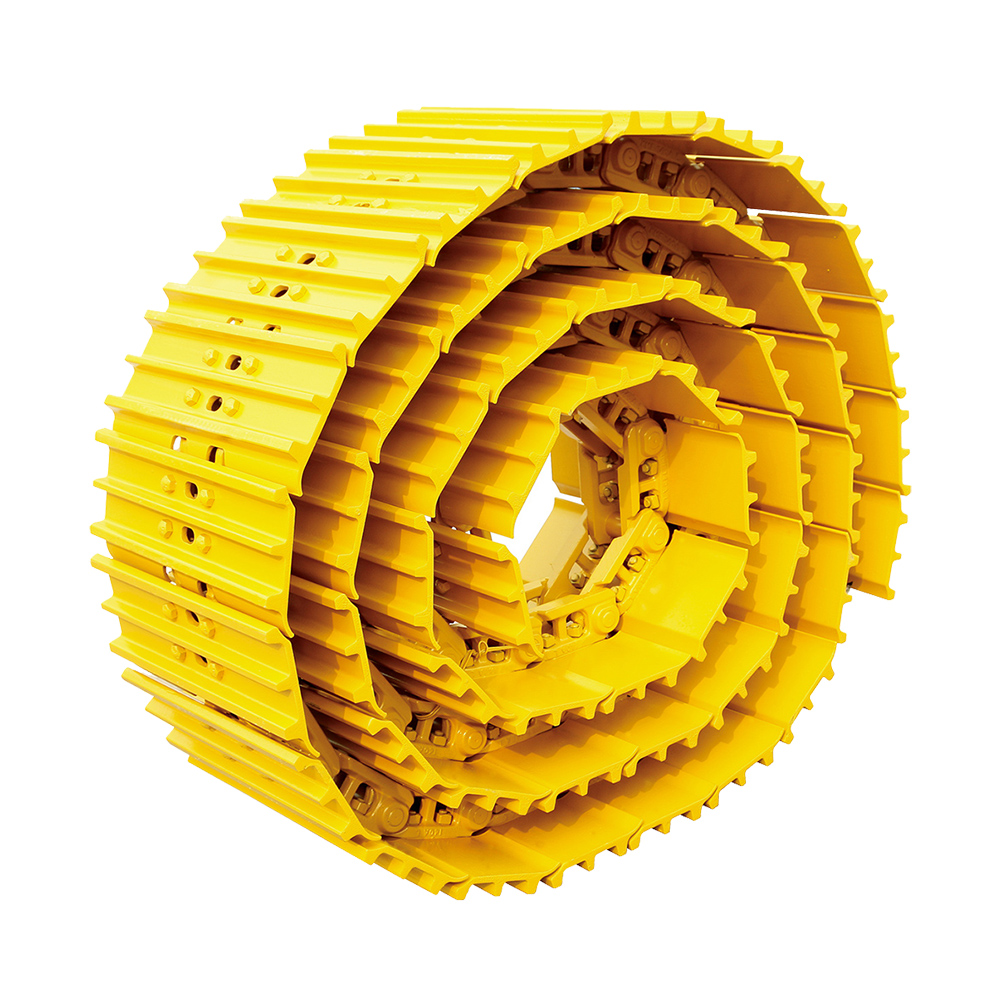

The function of carrier rollers is to carry the track link upwards, make certain things are linked tightly, and enable the machine to work faster and more steadily . Our products use special steel and produced by new process. Every procedure goes through strict inspection and the property of compressive resistance and tension resistance can be ensured.

The material of the carrier roller body is forged by 40Mn2. and the surface heat treatment HRC 48-55 depth up to 5-8mm. Precision CNC machine machining size is more accurate

The center shaft of the carrier roller material is 42CrMo and forged .The hardness of surface heat treatment can reach 48-55HRC More wear-resisting . Core hardness of HRC 28 or above is not easy to fracture. Tempering 180 degrees before finishing. The surface of the center shaft of the carrier roller is polished by CNC machine tool to make the shaft smoother.

High sealing aprons are used inside the carrier roller to prevent dirt, sand and water from damaging it.

The carrier roller using friction welding technology welding quality is good and stable, and environmental protection, no pollution.Welding process does not produce smoke or harmful gas, no splash, no lone light and spark, no radiation.Known as the green welding technology of the future.

| Description: | CAT D11 CARRIER ROLLER MINING OPERATION |

| Place of origin: | China |

| Brand name: | PT’ZM |

| Model number | |

| Brand: | Caterpillar |

| Price: | Negotiate |

| Packaging details: | Fumigate seaworthy packing |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 2000 PCS/month |

| Material: | 40Mn2/42Crmo |

| Technique: | Forging |

| Finish: | Smooth |

| Hardness: | HRC48-55, deepth 5-8mm |

| Quality: | mining operation |

| Warranty time: | 1600hours |

| After-sales service: | Video technical support,Online support |

| Color: | Yellow or Black or Customer required |

| Application: | Bulldozer & Crawler excavator |

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Hot-selling Excavator Final Drive Parts - Carrier Roller Mining Operation – Pingtai , The product will supply to all over the world, such as: Namibia, New York, Holland, Our company now has many department, and there have more than 20 employees in our company. We set up sales shop, show room, and product warehouse. In the meantime, we registered our own brand. We've got tightened inspection for quality of product.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.