Professional China Weld On Bucket Teeth - PC400 Carrier Roller Manufacturers 208-30-00320 – Pingtai

Professional China Weld On Bucket Teeth - PC400 Carrier Roller Manufacturers 208-30-00320 – Pingtai Detail:

Komatsu PC400 series undercarriage parts are specifically designed to provide extended life and durability for the toughest working conditions. Excellent after-service with leading industry warranty time 6 months to 2 years. The function of carrier rollers is to carry the track link upwards, make certain things are linked tightly, and enable the machine to work faster and more steadily . Our products use special steel and produced by new process. Every procedure goes through strict inspection and the property of compressive resistance and tension resistance can be ensured. The more advantages as following:

The material of the carrier roller body is forged by 40Mn2. and the surface heat treatment HRC 48-55 depth up to 5-8mm. Precision CNC machine machining size is more accurate

The center shaft of the carrier roller material is 42CrMo and forged .The hardness of surface heat treatment can reach 48-55HRC More wear-resisting . Core hardness of HRC 28 or above is not easy to fracture. Tempering 180 degrees before finishing. The surface of the center shaft of the carrier roller is polished by CNC machine tool to make the shaft smoother.

High sealing aprons are used inside the carrier roller to prevent dirt, sand and water from damaging it.

The carrier roller using friction welding technology welding quality is good and stable, and environmental protection, no pollution.Welding process does not produce smoke or harmful gas, no splash, no lone light and spark, no radiation.Known as the green welding technology of the future.

|

Product detail information |

|

|

Description: |

Carrier Roller Mining Operation Heavy duty |

|

Place of origin: |

China |

|

Brand name: |

PT’ZM |

|

Brand name: |

Komatsu |

|

Model number |

PC400-5 / PC450-6 |

|

Part number |

208-30-00320 |

|

Part number |

208-30-15102 |

|

Price: |

Negotiate |

|

Packaging details: |

Fumigate seaworthy packing |

|

Delivery time: |

7-30 days |

|

Payment term: |

L/C T/T |

|

Price term: |

FOB/ CIF/ CFR |

|

Minimum order quantity: |

1 PC |

|

Supply Ability: |

10000 PCS/month |

|

Material: |

40Mnb2/42Crmo |

|

Technique: |

Forging |

|

Finish: |

Smooth |

|

Hardness: |

HRC55-58, deepth 6-8mm |

|

Quality: |

mining operation heavy duty high-end quality |

|

Warranty time: |

24 months |

|

After-sales service: |

Video technical support,Online support |

|

Color: |

Black or Yellow or Customer required |

|

Application: |

Crawler Excavator |

|

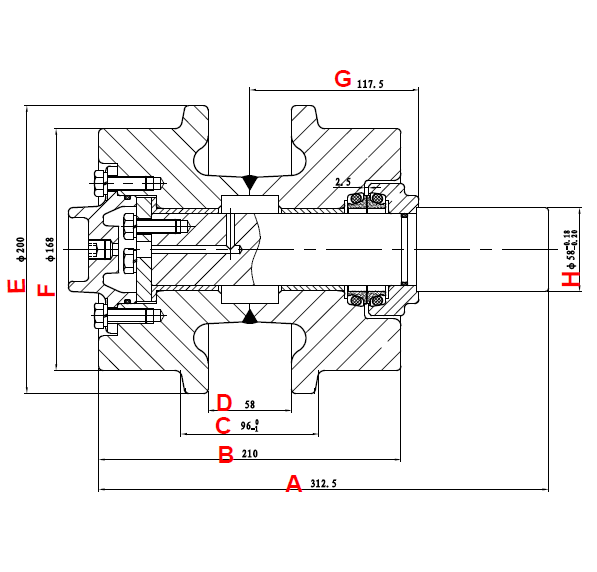

PC400 |

A |

B |

C |

D |

E |

F |

G |

H |

|

312.5 |

210 |

96 |

58 |

200 |

168 |

117.5 |

58 |

PC400-1, PC400-3, PC400-5, PC400-6, PC400-7, PC400HD-5, PC400LC-1, PC400LC-3, PC400LC-5, PC400LC-6, PC400LC-7, PC400LC-7E0, PC400LC-8

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and excellent excellent management throughout all stages of creation enables us to guarantee total buyer satisfaction for Professional China Weld On Bucket Teeth - PC400 Carrier Roller Manufacturers 208-30-00320 – Pingtai , The product will supply to all over the world, such as: Seattle, Puerto Rico, Turkey, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.