Quality Inspection for Belt Tracking Roller - Chain Hub Sprocket – Pingtai

Quality Inspection for Belt Tracking Roller - Chain Hub Sprocket – Pingtai Detail:

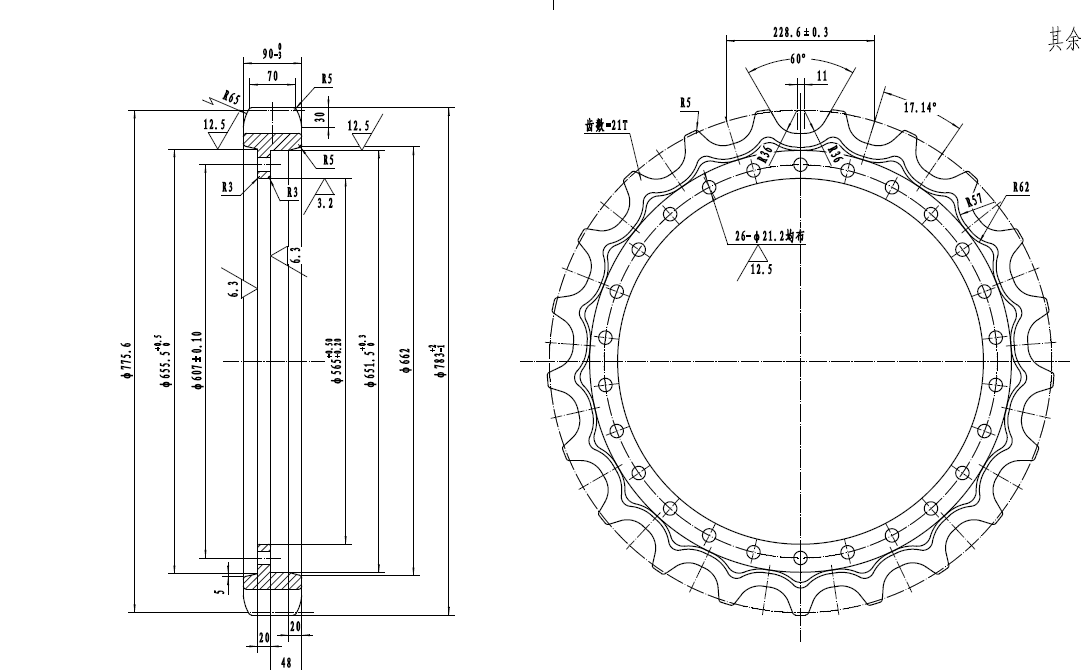

The driving wheel is composed of a walking motor, a walking deceleration mechanism and a sprocket . The hydraulic pressure from the autonomous pump can be rotated by the walking motor and decelerated by the walking deceleration mechanism.. Then the crawler chain with teeth or gears that engages with a chain, track, or other perforated or dented material. The sprocket is located at the front and rear of the vehicle to drive the rails.

Production process through professional quenching and tempering process, to ensure excellent mechanical properties, high strength and superior bending resistance, resistance to fracture and wear properties.

* Adopt advanced machining center and vertical CNC lathe to meet the precision requirements.

* Strict quality control, from raw materials to packaging.

* Surface hardness HRC50-60, reduces wear and tear, extends service life, and further adds value to your products by maximizing product durability. rail is driven by the sprocket installed on the shell to realize the excavator’s walking. A chain hub sprocket is a special-shaped wheel

Driving wheel: The driving wheel is located at the rear of X frame. The driving wheel is composed of a walking motor, a walking deceleration mechanism and a Chain hub sprocket .The hydraulic pressure from the autonomous pump can be rotated by the walking motor, which is decelerated by the walking deceleration mechanism. Then, the walking gear ring installed on the shell drives the track and chain rail to realize the walking of the excavator.

Driving wheel: The driving wheel is located at the rear of X frame. The driving wheel is composed of a walking motor, a walking deceleration mechanism and a Chain hub sprocket .The hydraulic pressure from the autonomous pump can be rotated by the walking motor, which is decelerated by the walking deceleration mechanism. Then, the walking gear ring installed on the shell drives the track and chain rail to realize the walking of the excavator.

One side of the driving wheel must always be in the rear, because it is directly fixed on the X frame without shock absorption function. If the driving wheel moves in the front, it will not only have abnormal wear on the driving ring gear and chain rail, but also have adverse effects on the X frame, which may have early cracking and other problems. Walking motor protector to protect the motor and its internal space can store some dirt and gravel, it will be harmful to walking motor oil pipeline, the moisture in the soil will corrosion of tubing, joint gravel will be involved in the interference caused by tubing wear leak, so regularly open the guard plate clean the dirt from the inside. When replacing the final transmission oil, the excavator should be parked on the flat ground, and the final transmission should be turned to the oil discharge port at the bottom and perpendicular to the ground. When refueling, tighten the oil discharge screw plug, refuel from the top of the refueling port, and the oil can flow out of the middle observation port.

| Description: | Chain hub sprocket forging / casting heavy duty |

| Place of origin: | China |

| Brand name: | PT’ZM |

| Model number | |

| Brand: | |

| Price: | Negotiate |

| Packaging details: | Fumigate seaworthy packing |

| Delivery time: | 7-30 days |

| Payment term: | L/C T/T |

| Price term: | FOB/ CIF/ CFR |

| Minimum order quantity: | 1 PC |

| Supply Ability: | 10000 PCS/month |

| Material: | ZG35SiMn |

| Technique: | Casting/Forging |

| Finish: | Smooth |

| Hardness: | HRC50-52 |

| Quality: | heavy duty mining operation |

| Warranty time: | 1600hours |

| After-sales service: | Video technical support,Online support |

| Color: | Yellow or Black or Customer required |

| Application: | Bulldozer & Crawler excavator |

Product detail pictures:

Related Product Guide:

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Quality Inspection for Belt Tracking Roller - Chain Hub Sprocket – Pingtai , The product will supply to all over the world, such as: belarus, Jakarta, Ecuador, The president and all the company members would like to provide professional products and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.